SPX

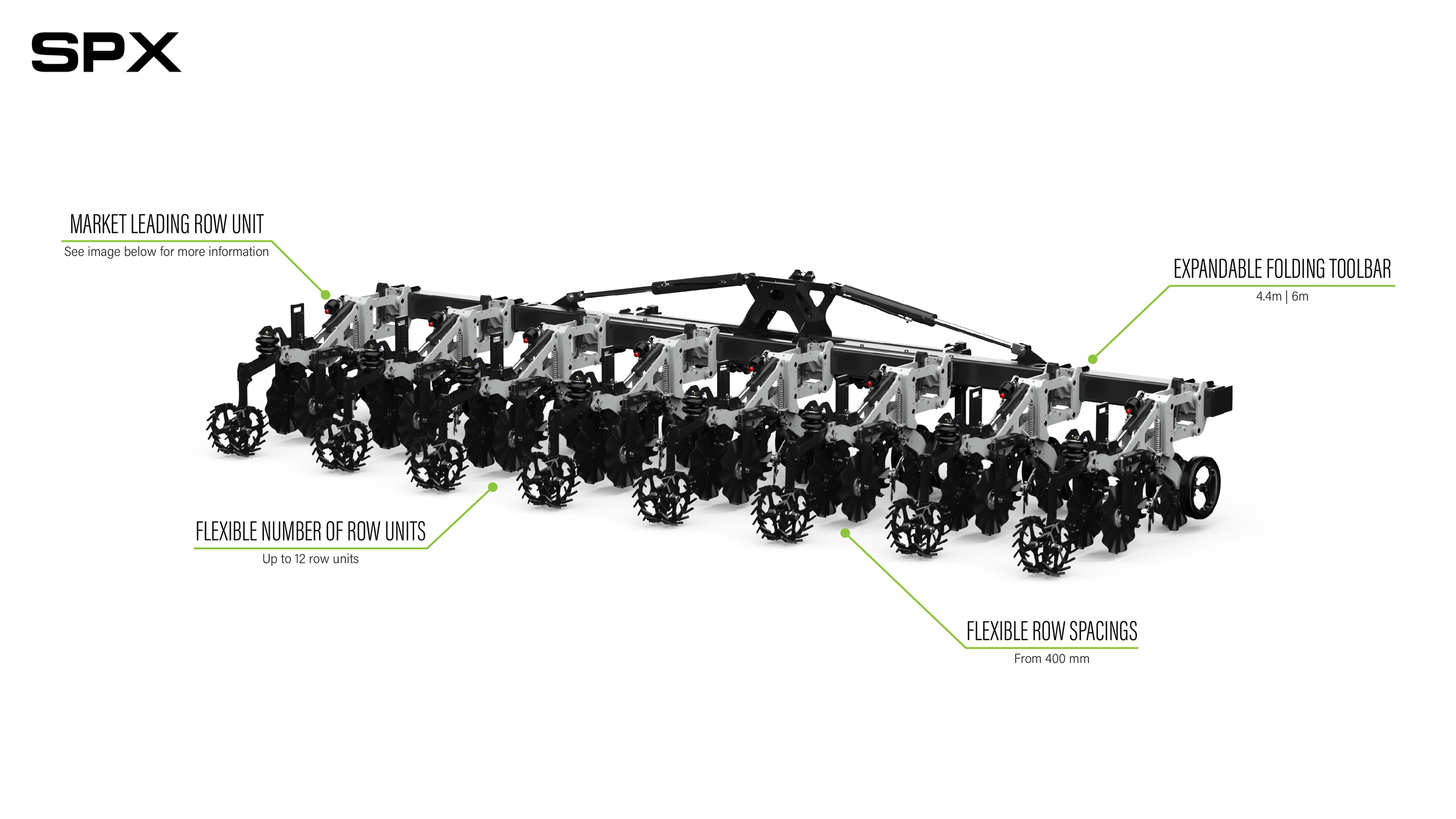

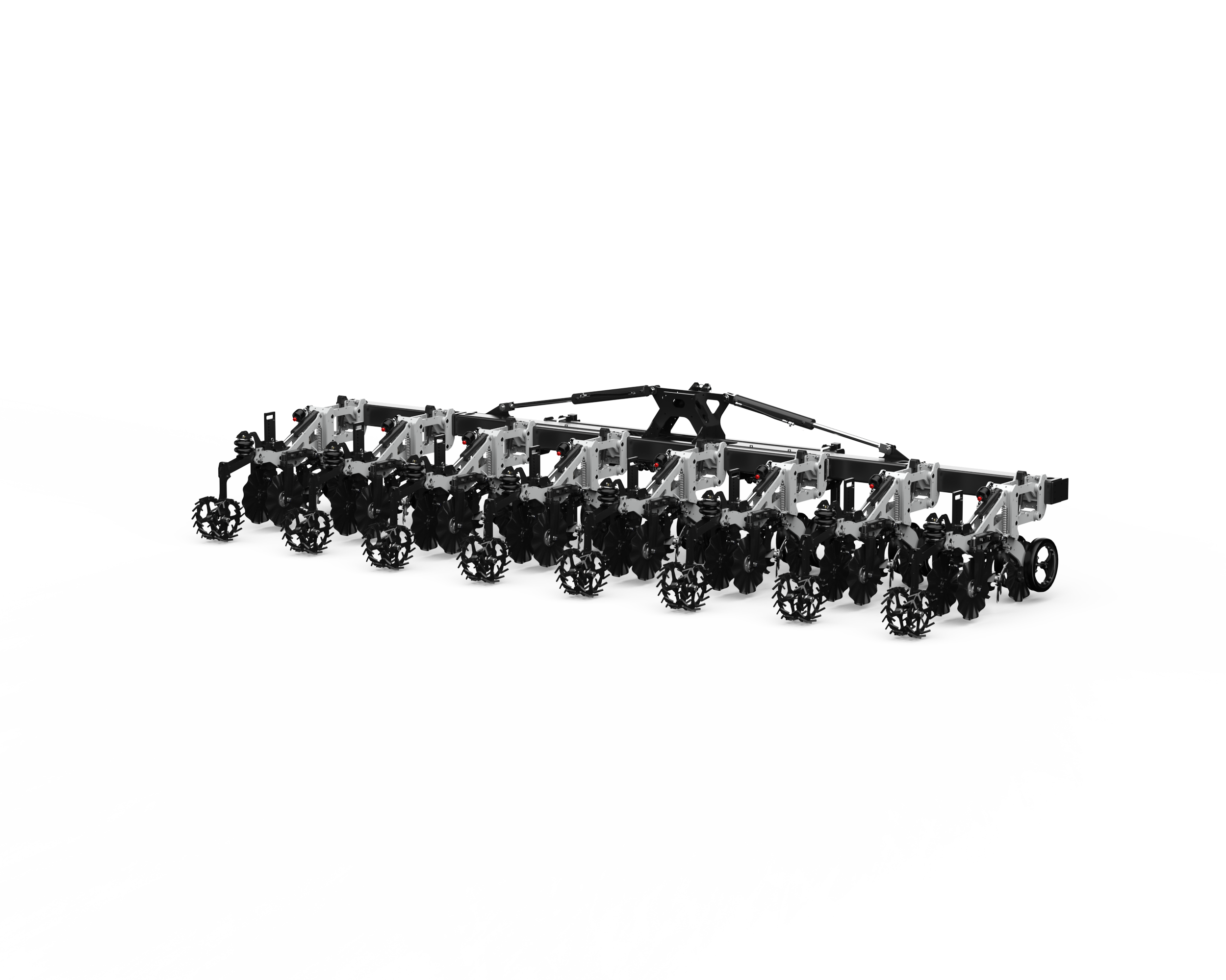

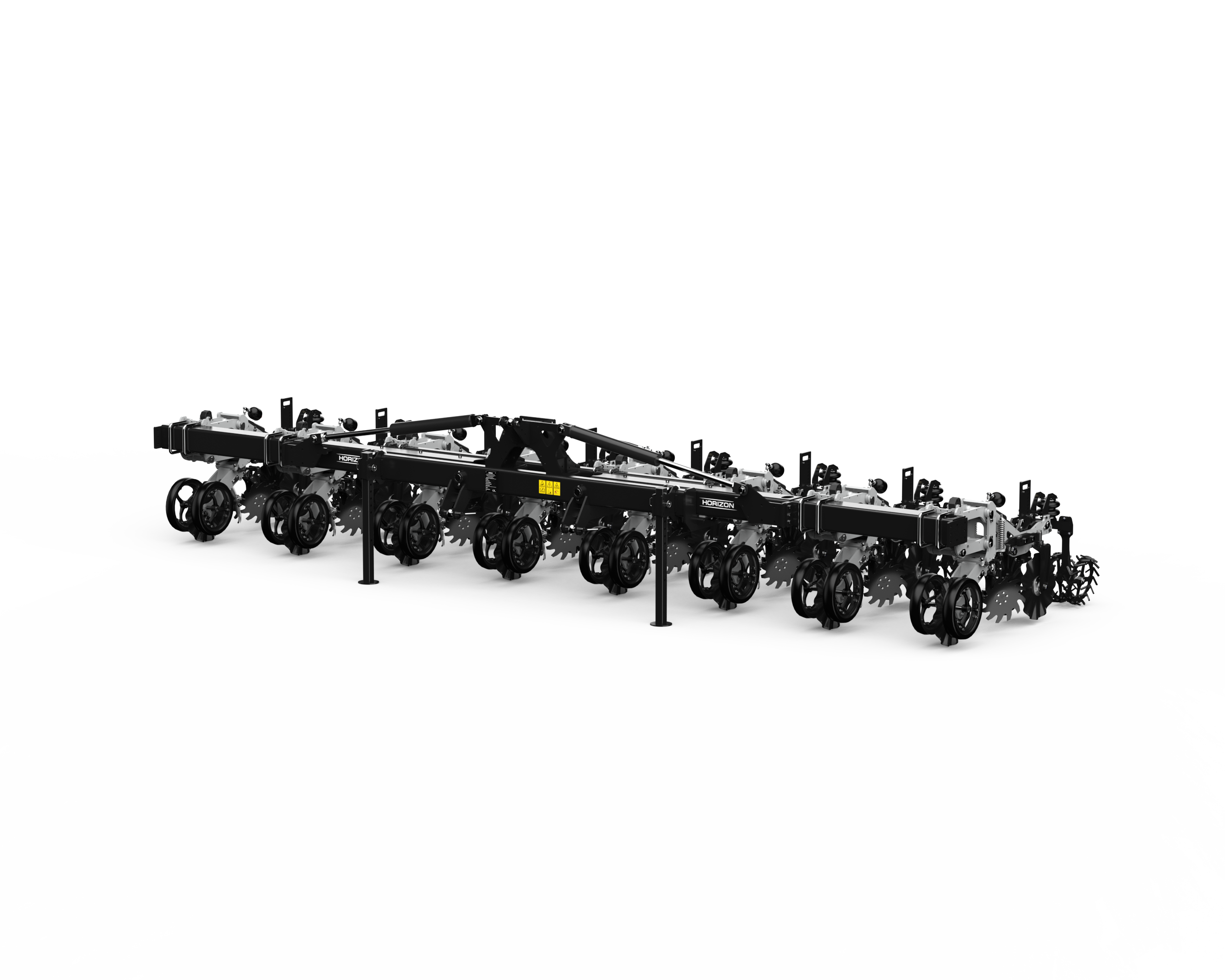

STRIP-TILL CULTIVATOR

The Horizon SPX strip-till system combines the process of conventional tillage with the soil-protecting advantages of no-till by disturbing only the portion of the soil that is to contain the seed row.

Horizon Agriculture possess over 15 years experience successfully applying strip tillage practices all over the world. With this wealth of knowledge, the Horizon SPX has been carefully designed with the ability to easily adapt to different applications and conditions.

The mounted toolbar is directly attached to the tractor’s 3-point linkage, allowing the SPX to perfectly follow the GPS which is essential for planter operations.

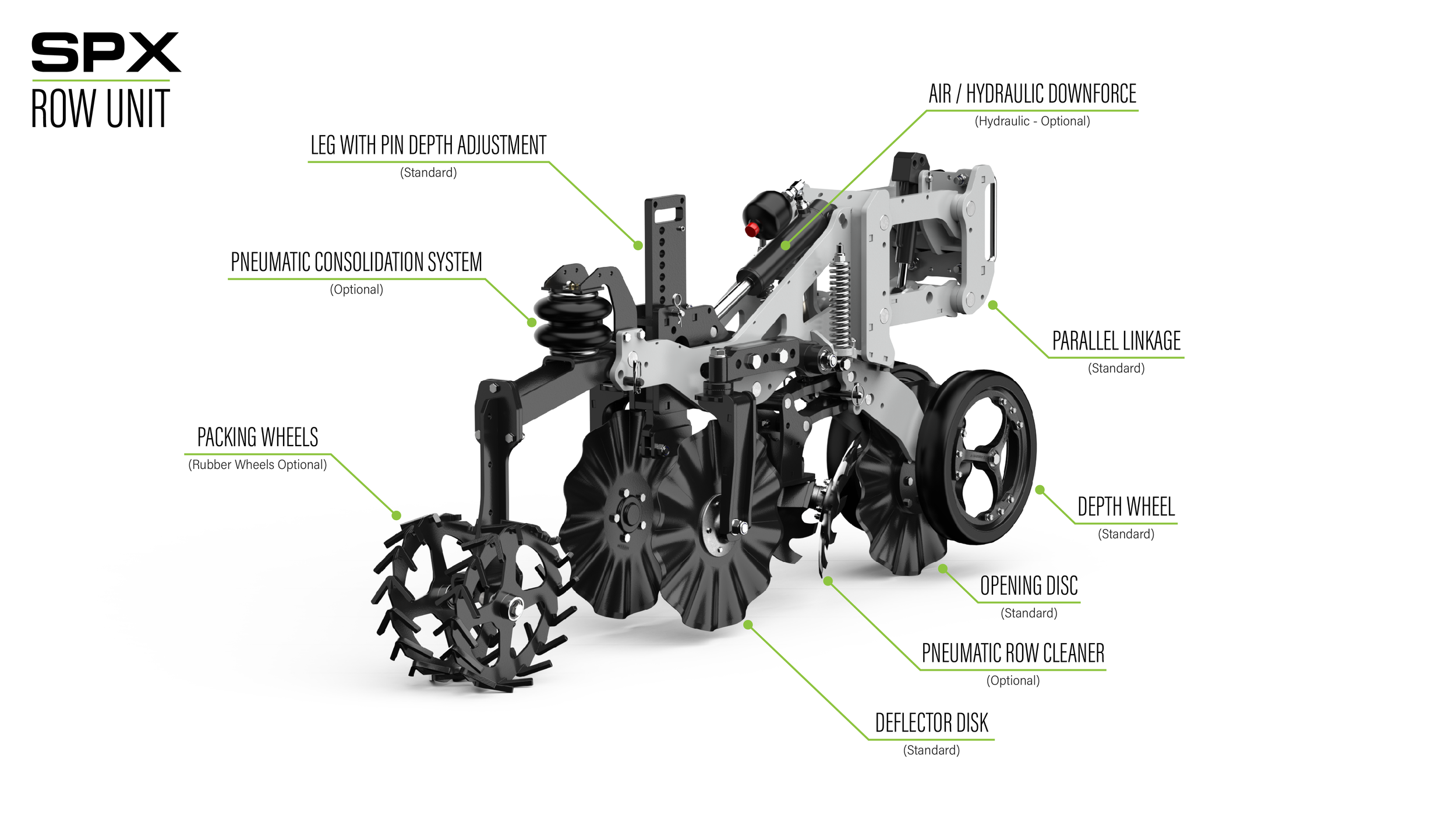

Pneumatically controlled row cleaners with CleanSweep technology can be adjusted in-cab for quick and accurate adjustment.

The positioning, widths and angles of the deflector discs can be easily adjusted offering multiple berm building options.

The pneumatic consolidation system with in-cab adjustment offers different wheel options for different soil types.

Why choose the Horizon SPX?

What is strip-tillage?

Strip-tillage combines the benefits of conventional tillage with the conservation-friendly advantages of no-till farming. Strip tilling reduces the risk of erosion, improves soil structure, enhances soil health and provides more stable footing for farm equipment.

To learn more about strip-tillage and the benefits it provides, click the button below to open our guide.

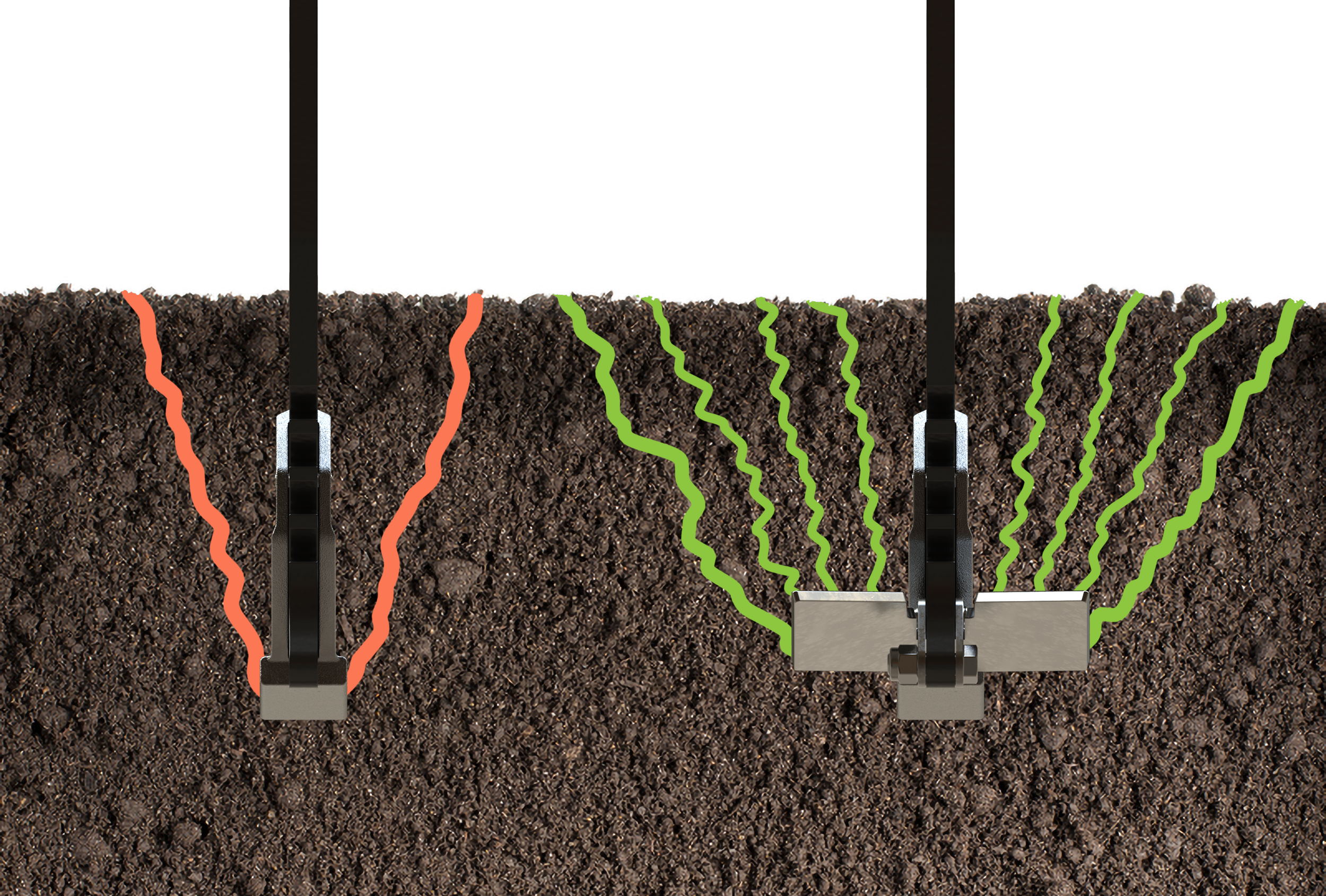

How does strip tillage work?

Strip tillage is a low disturbance, targeted tillage approach, consisting of only cultivating a narrow band of soil in which the crop is to be planted. This leaves lanes of uncultivated soil and residue on either side of the tilled strips over approximately two-thirds of the field surface.

Leaving these areas of undisturbed residue between the tilled planting strips is an excellent way to reduce risks of erosion, improve soil structure, enhance soil health and provide more stable footing for farm equipment.

For farmers with soils that are too challenging for a no-till system, strip tillage helps to allow farmers to break the soil up and alleviate compaction with a minimal effect on the microorganisms and other organic matter in the soil.

SPX strip-till features

Depth

The SPX can be operated to a depth of 40cm if required, however, in normal conditions, a depth of 15cm to 23cm is typical. A consideration when setting up the machine is that for every 5cm of depth, the draught force needed to pull the legs through the ground almost doubles, as well as increasing fuel consumption.

Tine

The tine assembly consists of the leg, shank, point and wing. Its purpose is to remove any compaction layers, move & fracture the soil, and place fertilizer accurately in the seeding zone (if fitted). Low and high disturbance points (27mm and 46mm), along with medium (130mm) and wide (160mm) wings are available to manage soil movement and lift.

Points and wing options

Points and wing options The SPX is able to be used with either low or high (27mm and 46mm) disturbance points and run with no wings, a 130mm wing or a 160mm wing to suit different applications.

The high disturbance point coupled with the 130mm wing is the factory standard specification, this gives good soil life/disturbance from the point whilst the wings are cracking the soil profile. If less soil boiling up is required, then switching to the low disturbance point is an option.

The deeper the SPX is working, then the higher the lift will need to be, consequently, increased lift should be by using the wider 160mm wings. While the addition of wings increases the draught force this is outweighed by increases in the amount of soil disturbance.

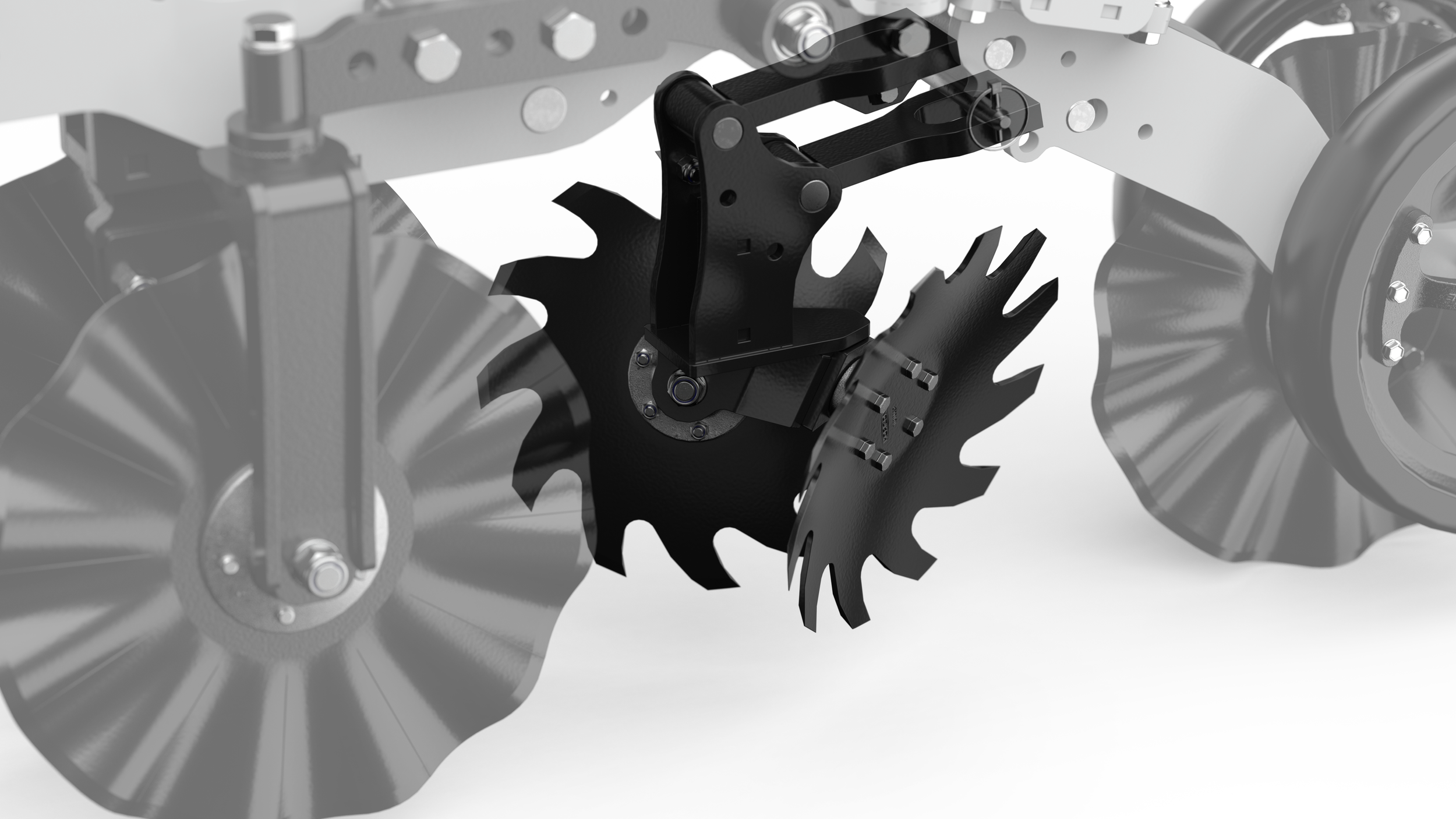

Row cleaners

For the majority of row crops to germinate effectively, it is essential that the seed is planted into trash-free soil. The optional SPX row cleaners, utilize market-leading CleanSweep technology from Precision Planting to remove all surface trash from the seeding zone.

Each row is equipped with a pneumatic cylinder to control the row cleaner operation, with an in-cab control box. It is important that the row cleaners do not operate directly on the ground as this will create a tillage effect resulting in excessive soil movement. The required pressures used will depend upon the row cleaners and field conditions.

Berm building discs

The berm discs manage the strip width and structure, by containing the soil brought up from the point and wing. Toe, width and lateral adjustments can be made to find the optimal setup. The width, angle and positioning of the discs can be adjusted according to the season and field conditions. Strip widths from 150mm to 300mm and a berm height of between 0mm and 100mm are achievable.

In the spring, the deflector discs can be set in a parallel position, leaving the strips level with the unmoved ground. In the autumn, the discs can be set at an angle, leaving the cultivated strip higher than the unmoved ground, allowing the soil to settle over winter.

Adjustments available for the SPX Strip-Till

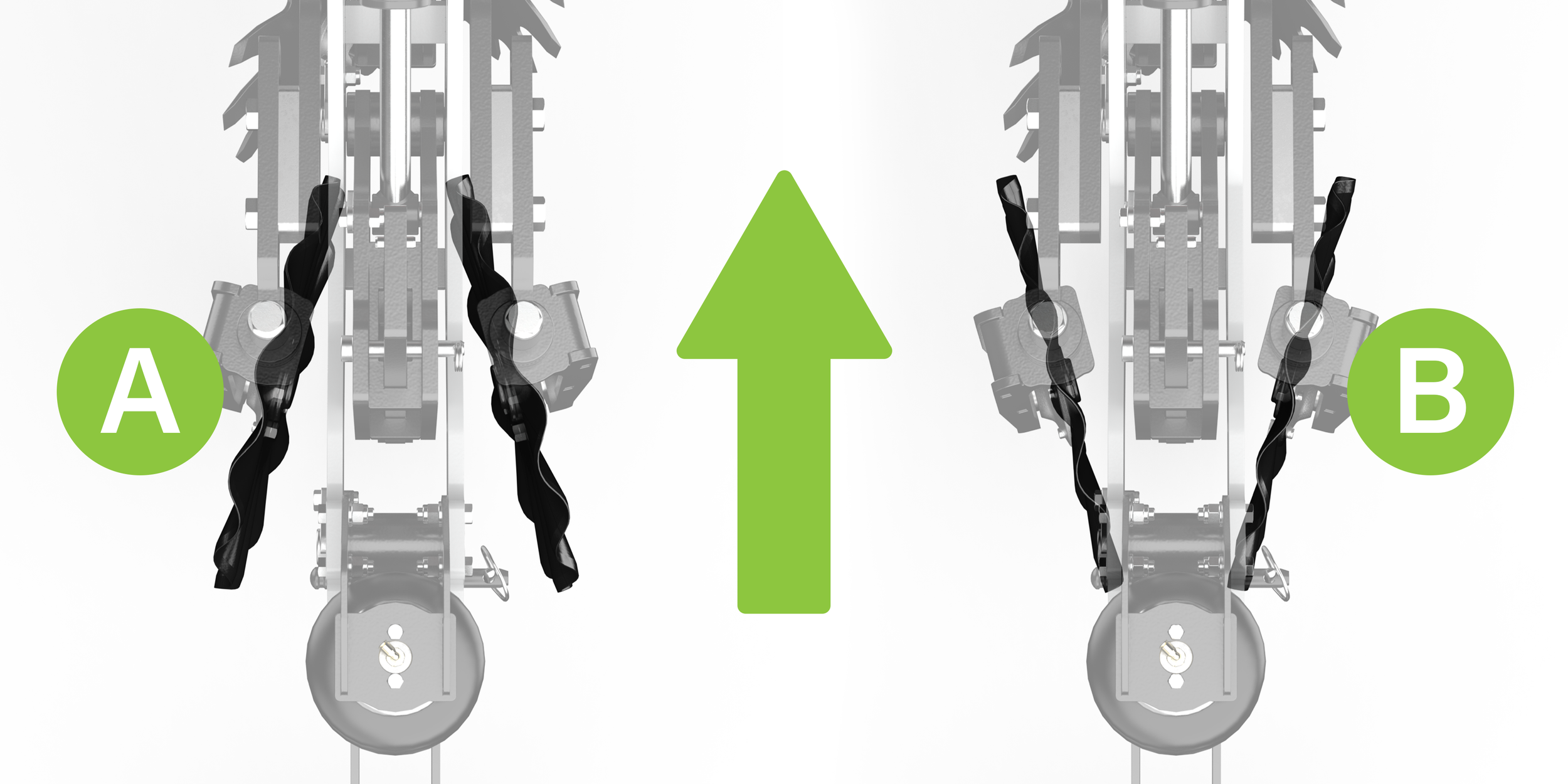

Berm Disc Toe-in (A)

This configuration allows the soil to flow easily out of the berm discs. This will create a shallow/lower strip.

Berm Disc Toe-out (B)

This configuration slows the soil from passing through the berm discs. This will create a wider/higher strip.

Width Adjustment

A narrow berm disc setting will increase the residue flow between the row units. It will contain soil between the discs and produce a more pronounced strip. A wide disc setting will decrease residue flow between the row units. It will allow more soil to pass between the discs and produce a less pronounced strip.

Fore/Aft Adjustment

The berm discs position can be adjusted forwards and backwards to determine the strip width and structure. Move the discs forward to increase the amount of escaping soil. Move the discs rearwards to reduce the amount of escaping soil. A higher strip will be built with the berm builders in a rearward position.

Each berm disc arm is held in place by a compression spring. The spring has two functions:

To allow the disc to ride over obstacles and to prevent component damage.

Enables the disc to cut into the soil and assist in building the strip structure.

Packing Wheel Pressure

Each row is equipped with a pneumatic airbag to control the closing wheel pressure on the row unit. The closing pressure can be controlled via the supplied box from the tractor cab, or manually with the fitted Shrader valves.

Note: If you strip-tillage in the spring in front of the planter, make sure an air pocket is not left in the seeding zone, the danger is the seed falls into this deep air pocket and/or does not have good seed-to-soil contact to germinate. To avoid this risk, make sure the rear packer wheels have enough pressure to push the lifted soil back down.

The packing wheels on the SPX can be mechanically locked in the raised position for the following reasons: Damp soil conditions, or the strips do not require any firming e.g. when stripping in the autumn on heavy land and frost weathering is required to help produce a tilth in the following spring, so the berm is intentionally left raised over winter.