TANKS

LIQUID FERTILISER TANKS

Bespoke liquid systems to suit your needs.

A liquid fertiliser tank is the perfect addition to all Horizon machines. Our liquid fertiliser system can be integrated onto a Horizon DSX, SPX and PPX, as well as machines from alternative manufacturers. Our tanks come complete with electric or hydraulic pumps, pipework, Wilger flow indicators and tablet-based control systems, ready for installation.

Why choose a Horizon Liquid Tank?

Each system can be configured to suit each customers unique needs

Every tank features an integrated clean water supply

Modular pipework

3 point hitch mounted

GPS speed sensor to eliminate complicated wiring

Easy to read Wilger flow pressure indicators

Split tank option

Designed, developed and manufactured in Great Britain

Front Fertilizer Tanks

Three point hitch mounted.

All our front mounted tanks are three point hitch mounted, allowing them to be mounted to the front of the tractor. Select tanks can also be mounted on the rear of the DSX no-till disc drill. Capacities available are 1100L, 1500L, 1800L and 2200L. These capacities all include a 100L section for clean water, and the 2200L tank also features a split section with a 750L capacity.

All tanks are supplied with a full lighting pack including headlights, indicators and sidelights. All wiring and tractor harness are also included in the kit. A GPS speed sensor is used to eliminate complicating wiring when installing the tanks.

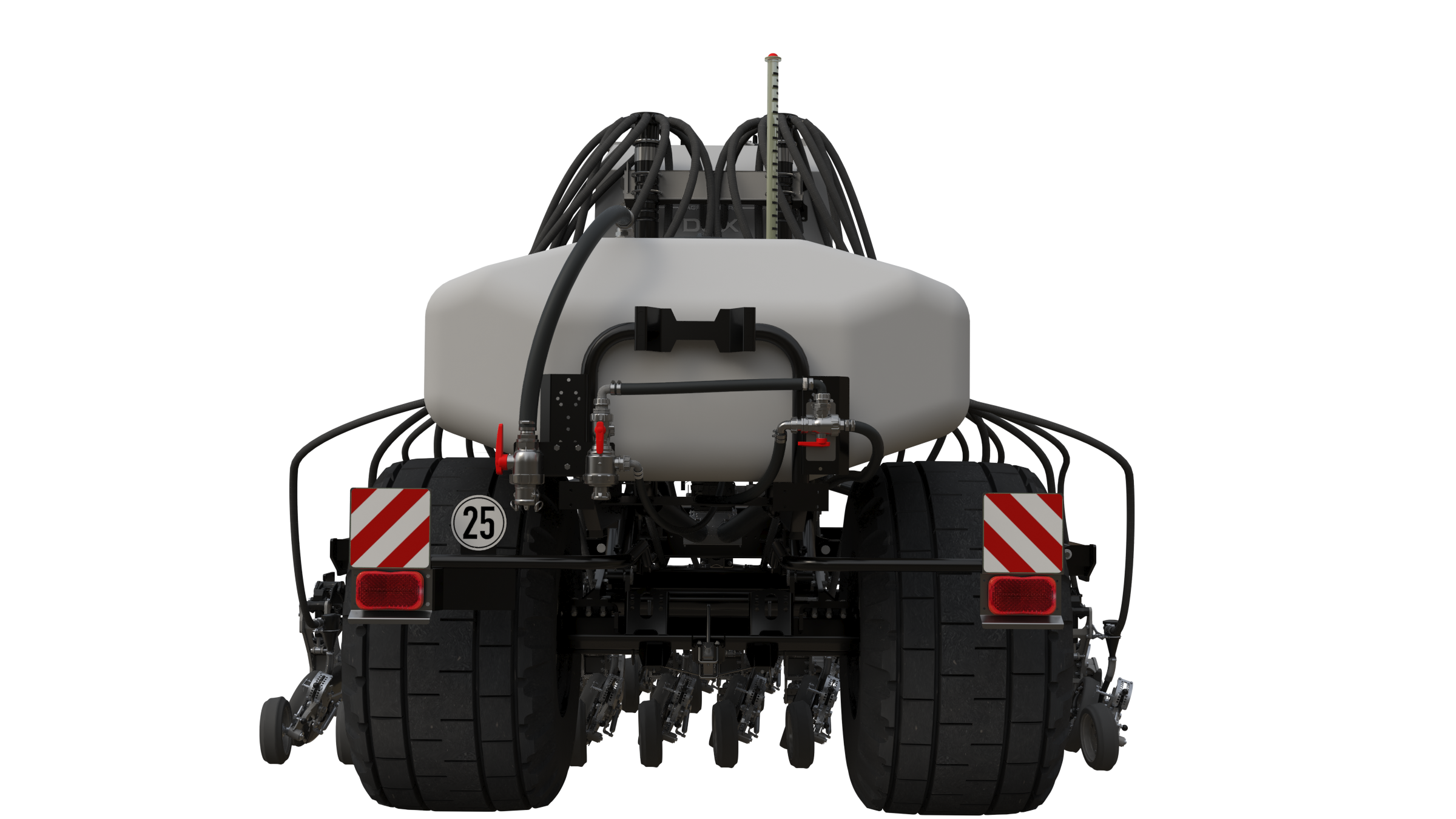

Rear Mounted Tanks

Designed to mount on our folding and rigid mounted frames.

Horizon Agricultural Machinery offer a liquid fertilizer tank designed to be mounted onto our PPX and MDSX frames. This stainless steel tank has a capacity of 750L for liquid fertilizer, with an additional 40L capacity for water. The tank features complete pipework and can be configured with either an electric or hydraulic pump, as well as wilger flow indicators.

Bespoke Systems to Suit Your Needs.

Fully modular configurations allow you to completely customize your systems.

Our liquid fertiliser systems feature modular pumps and pipework, allowing our customers to completely customize their systems to suit their needs. This includes a choice of different pump types, interchangeable regulators, a range of different flow sensors and Wilger flow indicators that can be specified to suit the amount of outlets.

Low Flow - Electric Pump

For machines with minimal outlets or low application rate requirements, our liquid fertilizer systems come equipped with an electric motor. These systems are capable of distributing up to 24L per minute across all outlets.

High Flow - Hydraulic Pump

For machines with more outlets or higher application rate requirements we offer a hydraulic pump. This pump is suited to distributing between 24L and 56L per minute.

Nutrient Placement

Ensuring your plant has the best possible start in life.

Accurately placing nutrients in the soil with the seed can dramatically improve emergence and vigour during the plants early growth stages. In comparison to broadcasting nutrients on the soil surface, placing nutrients in the soil during the planter pass will also reduce leaching and increase utilization which will therefore unlock opportunities to reduce application rates.

The Horizon PPX offers farmers the ability to place either granular or liquid fertilizers in the seed furrow and also in bands to the side of the seed. Typically Horizon PPX customers will place a phosphate based starter fertilizer in the seed furrow and a nitrogen based fertilizer to the side of the seed, perhaps 5cm away.

DSX Nutrient Delivery

DSX Row Unit Liquid Fertiliser Tube

A liquid fertiliser delivery tube can be mounted onto the DSX seed boot, allowing liquid fertiliser to be applied directly into the slot. Our liquid fertiliser tube is ideal for applying starter fertiliser to accompany the seed.

These tubes feature a stainless steel construction with a polymer inner, and are easy to clean and replace. They are easily mounted via two bolts onto the seed boot itself, ensuring accurate placement regardless of the wear of the disc or the seed boot itself.

PPX Nutrient Delivery

Dribble Bar.

The dribble bar can be mounted on the closing system of the row unit, and features stainless steel tubes. The dribble bar applies nitrogen on the surface of the soil, where it can safely soak and travel towards the seed without any risk of seed burn.

Seed Firmers.

Seed firmers such as the Keeton seed firmer can be used to apply phosphate or starter fertilizer directly into the slot with the seed. The seed firmer also ensures optimal seed-to-soil contact, which benefits emergence and yield.