DSX

The market leading no-till disc row unit. Designed and developed with the specific aim of overcoming the challenges of seeding with a no-till disc drill, our DSX Gen 3 row unit is capable of seeding with planter level depth accuracy and consistency.

GEN 3 ROW UNIT

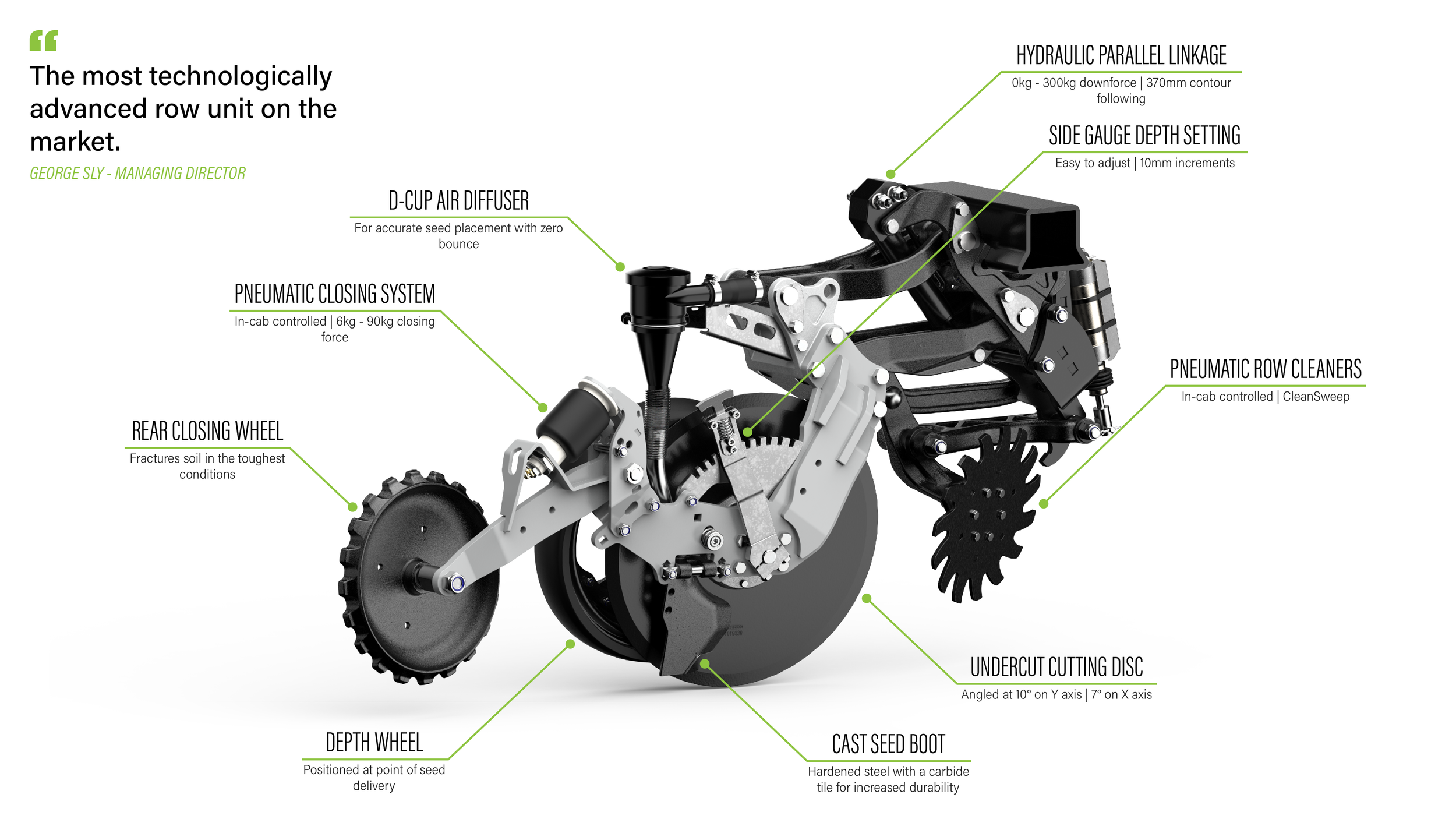

The most technologically advanced row unit on the market.

Our Gen 3 row unit stands as the most technologically advanced on the market, featuring a unique undercut disc design optimized through three generations of rigorous development. Each unit is mounted on a precision-engineered parallelogram linkage for consistent depth control, hydraulic downforce and pneumatic controls for both row cleaners and closing wheels. This advanced setup delivers precise seed placement and optimal residue management, setting a new standard in no-till seeding technology.

Market leading performance across wide variety of soil types and applications, and requires very little horsepower.

4cm narrower and 25kg lighter than our previous design, allowing even narrower row spacings and lighter machinery.

Features a reinforced parallelogram which makes the row unit stiffer whilst also able to travel 37cm for contour following.

Improved optional pneumatic row cleaner, now mounted on its own independent parallelogram extremely close to the disk to ensure debris cannot fall into the slot.

The Gen 3 row unit now clamps onto the toolbar, making the row unit even stiffer whilst allowing easier row spacing adjustment or removal.

New cast seed boot with tungsten carbide tile, dramatically increased durability whilst featuring a spring loaded design that automatically compensates for wear.

Same extremely successful undercut disc design with accurate depth control.

Why Choose the DSX Gen 3 Row Unit?

The DSX Row Unit Process

Clear, Cut and Close.

Clear and Manage Residue

Optional pneumatically controlled row cleaners clear debris from the path of the row unit, allowing seeds to be placed in slots clear of any residue.

Open the Slot and Place Seed

The DSX row unit’s undercut disc opens the soil and creates a flap. Thanks to the close proximity of the opener disc and gauge wheel, the depth of seeding is extremely accurate.

Closing the Slot

The rear closing wheel runs at an angle to fracture and consolidate the soil over the top of the seed, with the closing pressure pneumatically controlled from the cab.

Row Cleaner

Pneumatic Control From the Cabin.

Traditionally, row cleaners have been individually controlled through manual adjustment. This process is time consuming, especially in fields where conditions vary, and therefore provide a limited benefit to the farmer. Poor residue management due to ineffective row cleaners can lead to late emergence due to heat and moisture loss, seedling diseases and nutrients being lost as they are tied up by the residue.

Our pneumatically controlled row cleaners eliminate these issues, as the farmer can easily adjust all the row cleaners from the cabin while the machine is running. This means making adjustments for different areas of the field is easily done, and allows the row cleaners to operate much more effectively. In short, our pneumatically controlled row cleaners will save you time, save you from frustration and improve the chances for your crops.

Why Choose a Row Cleaner?

DEBRIS IN SLOT

NO DEBRIS IN SLOT

No till farming systems face both advantages and challenges when it comes to crop residue. One advantage is that much more crop residue is left on the surface of the soil, which both protects the soil from water erosion and contributes to soil tilth. However, whilst this residue benefits the soil it can cause problems when drilling seeds, as the residue can get trapped in the slot with the seed. This leads to poor soil-to-seed contact, with reduced germination and establishment. This is known as hair-pinning.

Our row cleaners mitigate the effects of hair-pinning. The row cleaners are pneumatically controlled from the cab and are mounted on their own independent parallel linkage, meaning they can easily and accurately be adjusted. The row cleaner disc itself is positioned extremely close to the opener disc, which minimizes the chance of any debris falling back into the slot. The images below show a slot created through thick chopped straw, which thanks to our row cleaner is completely clear of any debris.

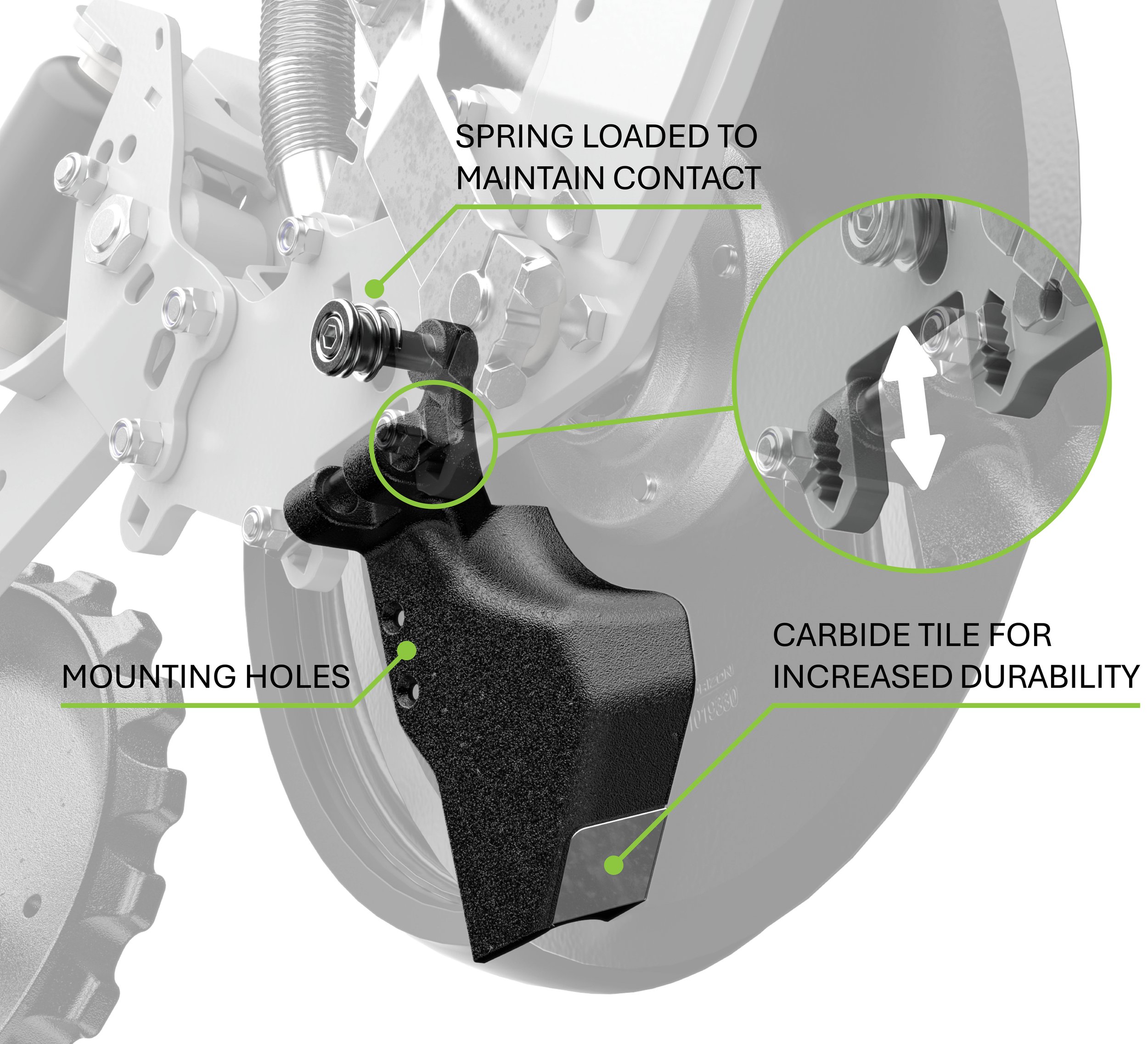

Seed Boot

Spring loaded, longer lasting.

The DSX row unit features a cast seed boot with a carbide tile for maximum durability. The seed boot is positioned in the shadow of the opener disc, ensuring clear and precise seed placement.

The seed boot is spring loaded to maintain contact against the opener disc whilst accounting for wear without any need for the operator to manually make adjustments. The height of the seed boot can also be adjusted to account for wear on the opener disc.

The seed boot features mounting holes, providing the opportunity for a seed firming device or liquid fertilizer applicator.

Reinforced Parallelogram

Stiffer design, more travel and lighter.

The Gen 3 row unit features a new parallelogram design which is lighter, narrower and stiffer. This new design also allows for an increase in overral travel, now capable of travelling 37cm. This means each row unit can confidently follow the contours of the soil, ensuring consistent planting depth across the full working width of the machine.

Clamping Toolbar

Stronger connection, easier row unit adjustment.

The Gen 3 DSX Row unit features a clamping system that allows virtually any row spacing to be configured by the farmer, as long as it is wider than our minimum. This clamping system also offers strength, durability and stiffness, meaning the row units will always track straight even in the hardest conditions. The row unit is held onto the toolbar with two M16 bolts, which can be loosed to either allow the row unit to slide, or to be removed completely.

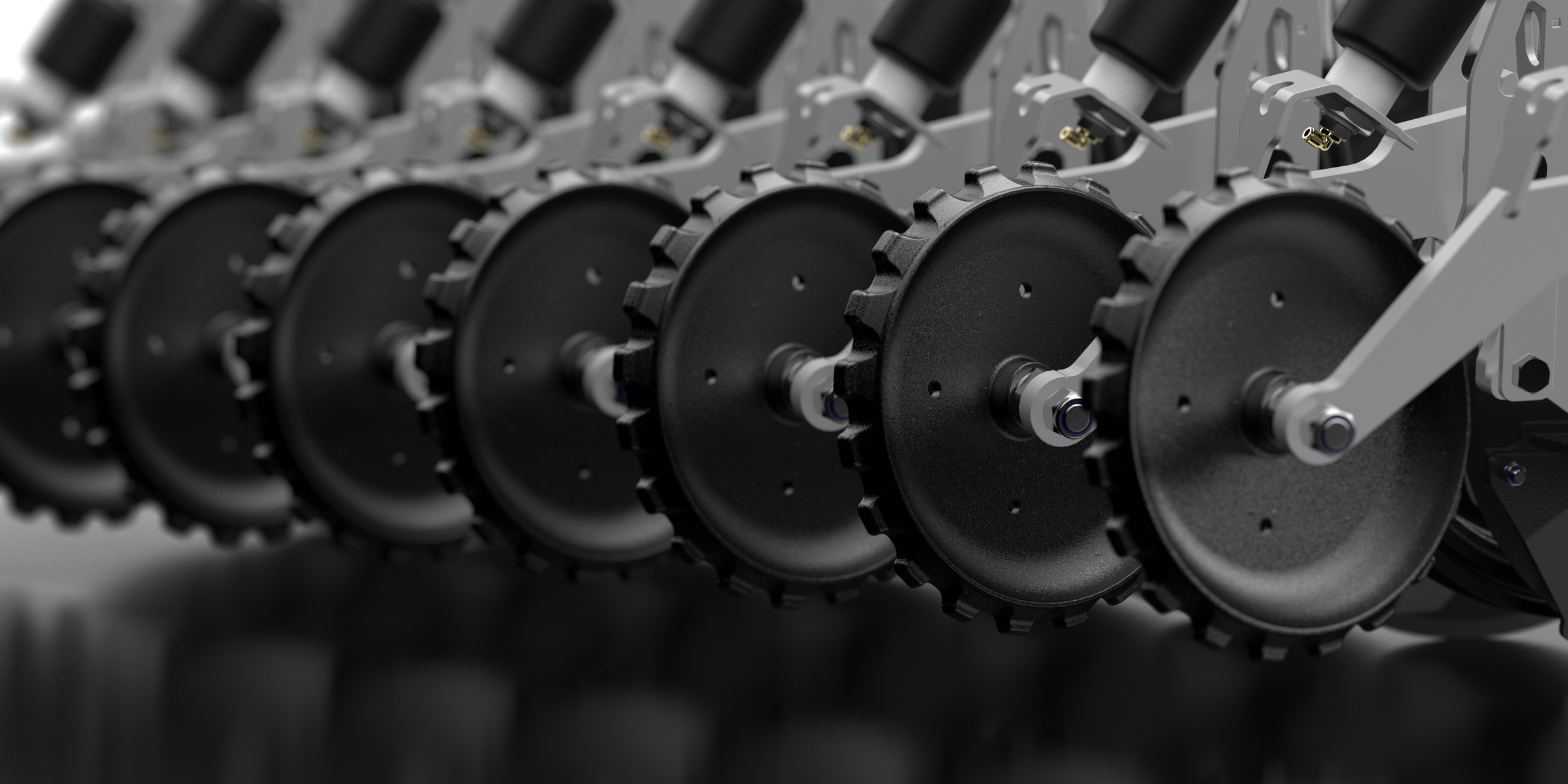

Closing

Pneumatically controlled, wheels for different soil types.

The DSX row units can be configured with either a notched cast-steel tooth closing wheel or a wider rubber wheel for lighter soils. The closing wheel angle can be adjusted to increase or decrease its closing aggressiveness, with an airbag that allows pneumatically controlled downforce to be adjusted from the cab. This ensures optimal closing in a wide variety of conditions and soil types, allowing our operators to drill all year round.

Diffusers

Eliminate seed bounce for perfect consistency.

To reduce the velocity of the seed and mitigate any risk of seed bounce (seed bouncing out of the slot due to a high pressure airflow), the DSX row unit features diffuser cups. These divert the pressurized airflow from the DSX turbine upwards, leaving the seed to fall through the seed boot and into the slot with minimal pressure.